Nvidia provides Omniverse Blueprint for AI factory digital twins

NVIDIA Unveils Major Expansion of Omniverse Blueprint for AI Factory Digital Twins

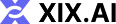

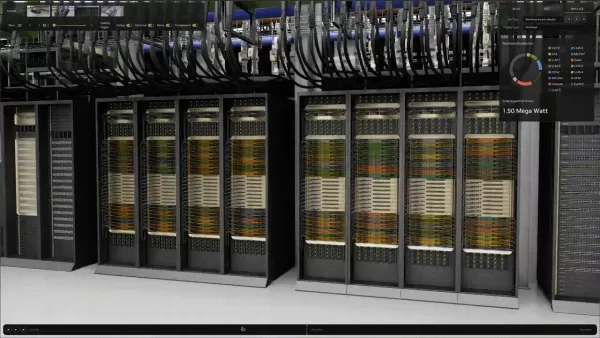

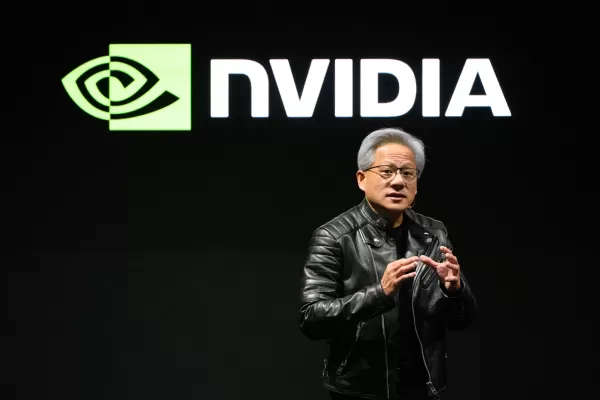

In a major announcement at Computex 2025 in Taipei, NVIDIA has significantly broadened the scope of its Omniverse Blueprint for AI Factory Digital Twins, now available as a preview. This update comes as the world witnesses an unprecedented surge in demand for AI-driven manufacturing facilities, pushing the boundaries of what's possible in digital infrastructure.

New Partnerships Power AI Factory Ecosystem

The blueprint has been enhanced with fresh collaborations spanning the AI factory's power, cooling, and networking ecosystems. Industry giants like Delta Electronics, Jacobs, and Siemens have joined forces with existing partners Cadence, Schneider Electric with ETAP, and Vertiv. These partnerships aim to enable real-world preparation for constructing AI-powered factories, leveraging digital twins to simulate and optimize every aspect of the facility.

Unifying Billions of Components

With this expansion, the growing ecosystem now unites the design and simulation of billions of components necessary for creating digital twins of AI factories. Engineering teams can now craft, simulate, and refine entire AI factories in precise virtual environments. This approach ensures early detection of potential issues and facilitates the creation of smarter, more dependable facilities.

Precision and Efficiency at Scale

Built on reference architectures powered by NVIDIA's GB200 NVL72 AI factories, the blueprint leverages Universal Scene Description (OpenUSD) asset libraries. This allows developers to consolidate detailed 3D and simulation data representing all elements of the data center into a single, cohesive model. As a result, they can design and simulate advanced AI infrastructure tailored for maximum efficiency, throughput, and resilience.

- Unified Simulation: The Omniverse Blueprint unifies AI factory power, cooling, and networking components in one comprehensive simulation.

- Collaborative Effort: Diverse partners like Siemens, Delta Electronics, and Jacobs are contributing to the framework, ensuring accuracy and functionality.

Driving Innovation Through Collaboration

Siemens is actively creating 3D models aligned with the blueprint and participating in the SimReady standardization initiative. Meanwhile, Delta Electronics is incorporating its equipment models, which are crafted using OpenUSD, guaranteeing authentic simulations of facility equipment. Jacobs is assisting in testing and refining the end-to-end blueprint workflow.

These additions complement leaders in data center power and cooling solutions such as Schneider Electric with ETAP and Vertiv, who are providing SimReady assets to populate the AI factory digital twin with 3D representations of power, cooling, and mechanical systems.

Optimizing Energy Efficiency

As Tanuj Khandelwal, CEO of ETAP, stated, "AI factories are redefining the digital infrastructure landscape. Using the Omniverse Blueprint and SimReady assets, customers can simulate and enhance energy efficiency for their AI workloads before construction begins."

Connections to the Cadence Reality Digital Twin Platform and ETAP offer thermal and power simulations. This allows engineering teams to evaluate and fine-tune power, cooling, and networking systems well before any bricks are laid.

A Smarter Approach to Infrastructure

Ben Gu, Corporate Vice President of R&D for Multiphysics System Analysis at Cadence, highlighted the importance of digital twins in meeting global AI factory demands. "The integration of the Cadence Reality Digital Twin Platform with the NVIDIA Omniverse Blueprint transforms the engineering process, enabling more efficient design and effective operation of AI factories."

Standardizing Simulations

A key advancement in this blueprint is the SimReady standardization workflow. Initially developed internally by NVIDIA to streamline the creation of OpenUSD assets, this publicly accessible tool provides standardized guidelines for developing SimReady capabilities. It empowers data center developers and operators to efficiently establish, optimize, and rigorously test their digital twins, particularly for electrical and thermal management within AI factories.

Charting a Smarter Path Forward

The expansion of the NVIDIA Omniverse Blueprint for AI Factory Digital Twins represents a monumental step toward designing, simulating, and deploying the sophisticated infrastructure needed for industrial AI. By offering a unified, physically accurate digital twin built on OpenUSD and guided by SimReady standards, this blueprint minimizes risks, enhances performance, and accelerates the rollout of next-generation AI factories.

Related article

Two Charged in Scheme to Illegally Export AI Chips to China

The U.S. Department of Justice (DOJ) announced Tuesday that two Chinese nationals were apprehended for allegedly orchestrating the illegal export of high-performance AI chips, valued at tens of millio

Two Charged in Scheme to Illegally Export AI Chips to China

The U.S. Department of Justice (DOJ) announced Tuesday that two Chinese nationals were apprehended for allegedly orchestrating the illegal export of high-performance AI chips, valued at tens of millio

Oracle's $40B Nvidia Chip Investment Boosts Texas AI Data Center

Oracle is set to invest approximately $40 billion in Nvidia chips to power a major new data center in Texas, developed by OpenAI, as reported by the Financial Times. This deal, one of the largest chip

Oracle's $40B Nvidia Chip Investment Boosts Texas AI Data Center

Oracle is set to invest approximately $40 billion in Nvidia chips to power a major new data center in Texas, developed by OpenAI, as reported by the Financial Times. This deal, one of the largest chip

Nvidia’s Earnings: Beyond Export Restrictions to New Hardware Demand

Nvidia will announce its fiscal 2026 first-quarter earnings, ending April 27, after market close on Wednesday.While U.S. chip export controls have stirred concerns about Nvidia’s global chip sales and

Comments (3)

0/200

Nvidia’s Earnings: Beyond Export Restrictions to New Hardware Demand

Nvidia will announce its fiscal 2026 first-quarter earnings, ending April 27, after market close on Wednesday.While U.S. chip export controls have stirred concerns about Nvidia’s global chip sales and

Comments (3)

0/200

![StephenLee]() StephenLee

StephenLee

August 25, 2025 at 1:33:49 AM EDT

August 25, 2025 at 1:33:49 AM EDT

Super cool to see NVIDIA pushing AI factory digital twins with Omniverse Blueprint! 🚀 Wonder how this'll shake up manufacturing efficiency.

0

0

![ScottAnderson]() ScottAnderson

ScottAnderson

August 10, 2025 at 11:00:59 AM EDT

August 10, 2025 at 11:00:59 AM EDT

This NVIDIA Omniverse update sounds like a game-changer for AI factories! 😮 I wonder how these digital twins will reshape manufacturing efficiency.

0

0

![NicholasThomas]() NicholasThomas

NicholasThomas

July 27, 2025 at 9:20:02 PM EDT

July 27, 2025 at 9:20:02 PM EDT

NVIDIA's Omniverse Blueprint sounds like a game-changer for AI factories! 🏭 The idea of digital twins is wild—imagine simulating entire production lines before building them. Saves time and cash! But I wonder, how accessible is this for smaller companies? 🤔

0

0

NVIDIA Unveils Major Expansion of Omniverse Blueprint for AI Factory Digital Twins

In a major announcement at Computex 2025 in Taipei, NVIDIA has significantly broadened the scope of its Omniverse Blueprint for AI Factory Digital Twins, now available as a preview. This update comes as the world witnesses an unprecedented surge in demand for AI-driven manufacturing facilities, pushing the boundaries of what's possible in digital infrastructure.

New Partnerships Power AI Factory Ecosystem

The blueprint has been enhanced with fresh collaborations spanning the AI factory's power, cooling, and networking ecosystems. Industry giants like Delta Electronics, Jacobs, and Siemens have joined forces with existing partners Cadence, Schneider Electric with ETAP, and Vertiv. These partnerships aim to enable real-world preparation for constructing AI-powered factories, leveraging digital twins to simulate and optimize every aspect of the facility.

Unifying Billions of Components

With this expansion, the growing ecosystem now unites the design and simulation of billions of components necessary for creating digital twins of AI factories. Engineering teams can now craft, simulate, and refine entire AI factories in precise virtual environments. This approach ensures early detection of potential issues and facilitates the creation of smarter, more dependable facilities.

Precision and Efficiency at Scale

Built on reference architectures powered by NVIDIA's GB200 NVL72 AI factories, the blueprint leverages Universal Scene Description (OpenUSD) asset libraries. This allows developers to consolidate detailed 3D and simulation data representing all elements of the data center into a single, cohesive model. As a result, they can design and simulate advanced AI infrastructure tailored for maximum efficiency, throughput, and resilience.

- Unified Simulation: The Omniverse Blueprint unifies AI factory power, cooling, and networking components in one comprehensive simulation.

- Collaborative Effort: Diverse partners like Siemens, Delta Electronics, and Jacobs are contributing to the framework, ensuring accuracy and functionality.

Driving Innovation Through Collaboration

Siemens is actively creating 3D models aligned with the blueprint and participating in the SimReady standardization initiative. Meanwhile, Delta Electronics is incorporating its equipment models, which are crafted using OpenUSD, guaranteeing authentic simulations of facility equipment. Jacobs is assisting in testing and refining the end-to-end blueprint workflow.

These additions complement leaders in data center power and cooling solutions such as Schneider Electric with ETAP and Vertiv, who are providing SimReady assets to populate the AI factory digital twin with 3D representations of power, cooling, and mechanical systems.

Optimizing Energy Efficiency

As Tanuj Khandelwal, CEO of ETAP, stated, "AI factories are redefining the digital infrastructure landscape. Using the Omniverse Blueprint and SimReady assets, customers can simulate and enhance energy efficiency for their AI workloads before construction begins."

Connections to the Cadence Reality Digital Twin Platform and ETAP offer thermal and power simulations. This allows engineering teams to evaluate and fine-tune power, cooling, and networking systems well before any bricks are laid.

A Smarter Approach to Infrastructure

Ben Gu, Corporate Vice President of R&D for Multiphysics System Analysis at Cadence, highlighted the importance of digital twins in meeting global AI factory demands. "The integration of the Cadence Reality Digital Twin Platform with the NVIDIA Omniverse Blueprint transforms the engineering process, enabling more efficient design and effective operation of AI factories."

Standardizing Simulations

A key advancement in this blueprint is the SimReady standardization workflow. Initially developed internally by NVIDIA to streamline the creation of OpenUSD assets, this publicly accessible tool provides standardized guidelines for developing SimReady capabilities. It empowers data center developers and operators to efficiently establish, optimize, and rigorously test their digital twins, particularly for electrical and thermal management within AI factories.

Charting a Smarter Path Forward

The expansion of the NVIDIA Omniverse Blueprint for AI Factory Digital Twins represents a monumental step toward designing, simulating, and deploying the sophisticated infrastructure needed for industrial AI. By offering a unified, physically accurate digital twin built on OpenUSD and guided by SimReady standards, this blueprint minimizes risks, enhances performance, and accelerates the rollout of next-generation AI factories.

Two Charged in Scheme to Illegally Export AI Chips to China

The U.S. Department of Justice (DOJ) announced Tuesday that two Chinese nationals were apprehended for allegedly orchestrating the illegal export of high-performance AI chips, valued at tens of millio

Two Charged in Scheme to Illegally Export AI Chips to China

The U.S. Department of Justice (DOJ) announced Tuesday that two Chinese nationals were apprehended for allegedly orchestrating the illegal export of high-performance AI chips, valued at tens of millio

Nvidia’s Earnings: Beyond Export Restrictions to New Hardware Demand

Nvidia will announce its fiscal 2026 first-quarter earnings, ending April 27, after market close on Wednesday.While U.S. chip export controls have stirred concerns about Nvidia’s global chip sales and

Nvidia’s Earnings: Beyond Export Restrictions to New Hardware Demand

Nvidia will announce its fiscal 2026 first-quarter earnings, ending April 27, after market close on Wednesday.While U.S. chip export controls have stirred concerns about Nvidia’s global chip sales and

August 25, 2025 at 1:33:49 AM EDT

August 25, 2025 at 1:33:49 AM EDT

Super cool to see NVIDIA pushing AI factory digital twins with Omniverse Blueprint! 🚀 Wonder how this'll shake up manufacturing efficiency.

0

0

August 10, 2025 at 11:00:59 AM EDT

August 10, 2025 at 11:00:59 AM EDT

This NVIDIA Omniverse update sounds like a game-changer for AI factories! 😮 I wonder how these digital twins will reshape manufacturing efficiency.

0

0

July 27, 2025 at 9:20:02 PM EDT

July 27, 2025 at 9:20:02 PM EDT

NVIDIA's Omniverse Blueprint sounds like a game-changer for AI factories! 🏭 The idea of digital twins is wild—imagine simulating entire production lines before building them. Saves time and cash! But I wonder, how accessible is this for smaller companies? 🤔

0

0