AI-Powered Maintenance Scheduling Transforms Efficiency in Revolutionary Way

In the bustling world of modern business, the key to keeping operations smooth and profitable lies in how well you manage your maintenance schedules. Gone are the days when we relied on cumbersome, error-prone manual methods. Enter artificial intelligence (AI), a game-changer that's revolutionizing how we approach maintenance scheduling, promising significant boosts in operational efficiency and cost savings. Let's explore how AI is transforming this crucial aspect of business management.

Key Points

- AI automates the scheduling process, slashing manual effort and boosting accuracy.

- It enables predictive maintenance, spotting potential equipment issues before they cause downtime.

- AI optimizes how resources are allocated, ensuring the right people and tools are in the right place at the right time.

- Dynamic scheduling powered by AI adapts to real-time changes, enhancing overall efficiency.

- Successful AI integration hinges on a solid data foundation and a strategic implementation plan.

The Challenges of Traditional Maintenance Scheduling

Time-Consuming Manual Processes

Traditional maintenance scheduling can feel like you're stuck in the last century, bogged down by manual data collection, analysis, and scheduling. Imagine your team buried under piles of maintenance logs, equipment manuals, and historical data, trying to figure out when and how to schedule maintenance tasks. It's not just a time sink; it's a breeding ground for errors. Missed tasks, unexpected equipment failures, and unplanned downtime are just some of the headaches that come with this outdated approach, directly hitting your productivity and profitability.

Lack of Predictive Capabilities

Without the foresight that predictive maintenance offers, you're often left scheduling maintenance based on a calendar or a gut feeling. This can lead to either too much maintenance, wasting time and money, or too little, risking sudden equipment failures. These failures can throw your operations into chaos, rack up repair bills, and tarnish your company's reputation. AI, on the other hand, gives you the power to anticipate and prevent such issues.

Inefficient Resource Allocation

Getting the right technicians, tools, and spare parts to the right place at the right time is no small feat with traditional methods. It's like trying to solve a puzzle blindfolded. This often results in delays, higher travel costs, and wasted resources. Clearly, we need a smarter, data-driven approach to manage our resources effectively.

Examples of AI Implementation in Maintenance Scheduling

Case Study: Manufacturing Plant Downtime Reduction

Take a manufacturing plant that decided to leap into the future with an AI-powered maintenance system. By analyzing sensor data from their equipment, the AI spotted a pump on the brink of failure. Thanks to this early warning, the plant scheduled a timely replacement, dodging a major breakdown that would have cost them dearly in downtime and repairs. It's a clear example of how AI can save you both time and money.

Example: Optimizing a Wind Turbine Farm’s Maintenance

Wind turbine farms are another great example of AI in action. AI systems keep an eye on turbine performance and wind conditions, scheduling maintenance when the wind is low or during predicted downtime. This smart scheduling minimizes disruptions to energy production and makes the best use of maintenance resources. Plus, it takes into account technician availability and travel costs, ensuring the most efficient team is on the job.

How to Integrate AI into Your Maintenance Scheduling

Building a Strong Data Foundation

To make AI work for you, you need a robust data foundation. That means gathering and organizing data from equipment sensors, maintenance logs, and historical performance records. This data needs to be spot-on, complete, and consistent so your AI can churn out reliable predictions and insights. Investing in your data infrastructure is a must to build a solid AI-powered maintenance system.

Selecting the Right AI Tools and Algorithms

Choosing the right AI tools and algorithms is crucial for getting the results you want. There's a whole world of AI solutions out there, each with its own strengths and weaknesses. You'll need to weigh your options carefully, considering the data you have, the complexity of your maintenance tasks, and how much automation you're aiming for. Tools like robotic process automation (RPA) or generative AI like ChatGPT can kickstart your journey.

Training and Upskilling Your Workforce

Implementing AI isn't just about the technology; it's also about your people. Your team needs to know how to use and interpret AI insights. That means investing in training and upskilling to equip your maintenance staff with the knowledge they need. It's also about fostering a culture that embraces data-driven decision-making, encouraging everyone to use AI to improve their work.

Adopting a Strategic Approach

Getting AI into your maintenance scheduling requires a strategic approach. You need to set clear goals, map out your implementation plan, and manage the change process carefully. Keep an eye on how the AI is performing and be ready to tweak things as needed to make sure it's delivering the results you're after.

The AI Advantage: Weighing the Pros and Cons of AI in Maintenance

Pros

- Boosts efficiency and cuts down on downtime.

- Drives data-driven decisions and optimizes resource use.

- Cuts maintenance costs and extends equipment life.

- Improves safety and compliance.

- Enhances productivity and profitability.

Cons

- Requires upfront investment in AI tools and infrastructure.

- Demands high-quality data and expertise.

- Risks job displacement and may face resistance to change.

- Poses cybersecurity and ethical challenges.

- Risks over-reliance on data and algorithms, leading to a 'black box' effect where decision-making becomes opaque.

FAQ

What types of maintenance can AI optimize?

AI can enhance various maintenance types, including preventative, predictive, and corrective, by analyzing data for better scheduling and resource management.

How does AI handle unexpected events in maintenance scheduling?

AI uses real-time data and dynamic algorithms to adjust maintenance tasks on the fly, ensuring minimal disruption.

What are the cybersecurity implications of using AI for maintenance scheduling?

Protecting sensitive maintenance data from cyber threats requires robust encryption, strict access controls, and continuous monitoring.

Can AI be used to improve maintenance scheduling in remote locations?

Absolutely, AI can optimize resource use and predict equipment failures in remote areas, leveraging cloud and edge computing solutions.

What type of business can benefit from AI maintenance?

From large enterprises to facility management, oil and gas companies, and even municipalities, many businesses can reap the benefits of AI in maintenance scheduling.

Related Questions

What are the potential long-term implications of AI in maintenance scheduling?

Integrating AI into maintenance scheduling heralds a future where predictive, efficient, and optimized operations become the norm. This shift not only cuts downtime and costs but also extends equipment life and fosters data-driven decision-making across industries. As AI evolves, we'll see more autonomous maintenance systems, real-time adaptive scheduling, and advanced predictive analytics, transforming traditional maintenance practices for good.

Related article

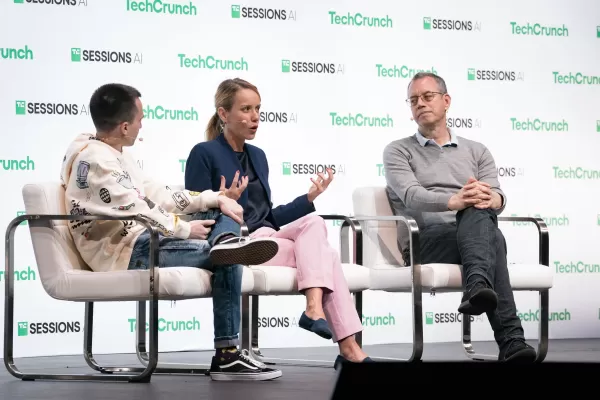

"Exploring AI Safety & Ethics: Insights from Databricks and ElevenLabs Experts"

As generative AI becomes increasingly affordable and widespread, ethical considerations and security measures have taken center stage. ElevenLabs' AI Safety Lead Artemis Seaford and Databricks co-creator Ion Stoica participated in an insightful dia

"Exploring AI Safety & Ethics: Insights from Databricks and ElevenLabs Experts"

As generative AI becomes increasingly affordable and widespread, ethical considerations and security measures have taken center stage. ElevenLabs' AI Safety Lead Artemis Seaford and Databricks co-creator Ion Stoica participated in an insightful dia

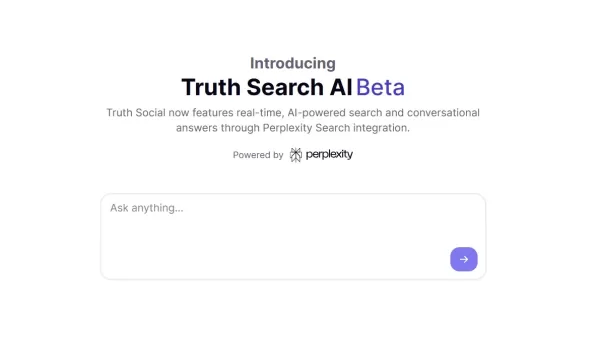

Truth Social’s New AI Search Engine Heavily Favors Fox News in Results

Trump's social media platform introduces an AI-powered search function with apparent conservative media slantExclusive AI Search Feature LaunchesTruth Social, the social media platform founded by Donald Trump, has rolled out its new artificial intell

Truth Social’s New AI Search Engine Heavily Favors Fox News in Results

Trump's social media platform introduces an AI-powered search function with apparent conservative media slantExclusive AI Search Feature LaunchesTruth Social, the social media platform founded by Donald Trump, has rolled out its new artificial intell

Cursor Acquires Koala in Bid to Compete With GitHub Copilot

The startup behind viral AI coding platform Cursor is aggressively recruiting top engineering talent from rival AI firms as it escalates competition with Microsoft's GitHub Copilot. Recent moves include acquiring talent from AI-powered CRM startup Ko

Comments (20)

0/200

Cursor Acquires Koala in Bid to Compete With GitHub Copilot

The startup behind viral AI coding platform Cursor is aggressively recruiting top engineering talent from rival AI firms as it escalates competition with Microsoft's GitHub Copilot. Recent moves include acquiring talent from AI-powered CRM startup Ko

Comments (20)

0/200

![KennethKing]() KennethKing

KennethKing

April 25, 2025 at 12:52:07 PM EDT

April 25, 2025 at 12:52:07 PM EDT

O agendamento de manutenção alimentado por IA realmente transformou a forma como gerenciamos nossas operações. É como ter um assistente inteligente que sabe exatamente quando as coisas precisam ser consertadas. Economiza muito tempo e reduz erros. Só queria que fosse um pouco mais barato! 😅

0

0

![NicholasYoung]() NicholasYoung

NicholasYoung

April 24, 2025 at 3:14:45 AM EDT

April 24, 2025 at 3:14:45 AM EDT

このAIツールを使ってから、メンテナンスのスケジュールが劇的に改善しました!まるで賢いアシスタントがいるみたい。ただ、最初の設定が少し難しいですね。それでも、使う価値は十分あります!🚀

0

0

![JackLewis]() JackLewis

JackLewis

April 23, 2025 at 5:04:17 PM EDT

April 23, 2025 at 5:04:17 PM EDT

AI-Powered Maintenance Scheduling has really transformed how we handle our operations. It's like having a smart assistant that knows exactly when things need fixing. Saves us so much time and reduces errors. Only wish it was a bit cheaper! 🤓

0

0

![RogerSanchez]() RogerSanchez

RogerSanchez

April 22, 2025 at 1:59:25 PM EDT

April 22, 2025 at 1:59:25 PM EDT

이 AI 도구를 사용한 이후로 유지보수 일정이 엄청나게 좋아졌어요! 마치 똑똑한 조수가 있는 것 같아요. 다만, 처음 설정하는 게 좀 어려워요. 그래도 사용할 가치는 충분해요! 🚀

0

0

![AlbertRodriguez]() AlbertRodriguez

AlbertRodriguez

April 21, 2025 at 11:26:10 PM EDT

April 21, 2025 at 11:26:10 PM EDT

Desde que começamos a usar essa ferramenta de AI, a programação de manutenção melhorou muito! É como ter um assistente superinteligente. A única coisa é que pode ser um pouco complicado configurar no início. Mas vale totalmente a pena! 🚀

0

0

![FrankMartínez]() FrankMartínez

FrankMartínez

April 21, 2025 at 6:01:52 PM EDT

April 21, 2025 at 6:01:52 PM EDT

This AI tool has seriously upped our game in maintenance scheduling! It's like having a super-smart assistant that keeps everything running smoothly. Only thing is, it can be a bit tricky to set up at first. Definitely worth the effort though! 🚀

0

0

In the bustling world of modern business, the key to keeping operations smooth and profitable lies in how well you manage your maintenance schedules. Gone are the days when we relied on cumbersome, error-prone manual methods. Enter artificial intelligence (AI), a game-changer that's revolutionizing how we approach maintenance scheduling, promising significant boosts in operational efficiency and cost savings. Let's explore how AI is transforming this crucial aspect of business management.

Key Points

- AI automates the scheduling process, slashing manual effort and boosting accuracy.

- It enables predictive maintenance, spotting potential equipment issues before they cause downtime.

- AI optimizes how resources are allocated, ensuring the right people and tools are in the right place at the right time.

- Dynamic scheduling powered by AI adapts to real-time changes, enhancing overall efficiency.

- Successful AI integration hinges on a solid data foundation and a strategic implementation plan.

The Challenges of Traditional Maintenance Scheduling

Time-Consuming Manual Processes

Traditional maintenance scheduling can feel like you're stuck in the last century, bogged down by manual data collection, analysis, and scheduling. Imagine your team buried under piles of maintenance logs, equipment manuals, and historical data, trying to figure out when and how to schedule maintenance tasks. It's not just a time sink; it's a breeding ground for errors. Missed tasks, unexpected equipment failures, and unplanned downtime are just some of the headaches that come with this outdated approach, directly hitting your productivity and profitability.

Lack of Predictive Capabilities

Without the foresight that predictive maintenance offers, you're often left scheduling maintenance based on a calendar or a gut feeling. This can lead to either too much maintenance, wasting time and money, or too little, risking sudden equipment failures. These failures can throw your operations into chaos, rack up repair bills, and tarnish your company's reputation. AI, on the other hand, gives you the power to anticipate and prevent such issues.

Inefficient Resource Allocation

Getting the right technicians, tools, and spare parts to the right place at the right time is no small feat with traditional methods. It's like trying to solve a puzzle blindfolded. This often results in delays, higher travel costs, and wasted resources. Clearly, we need a smarter, data-driven approach to manage our resources effectively.

Examples of AI Implementation in Maintenance Scheduling

Case Study: Manufacturing Plant Downtime Reduction

Take a manufacturing plant that decided to leap into the future with an AI-powered maintenance system. By analyzing sensor data from their equipment, the AI spotted a pump on the brink of failure. Thanks to this early warning, the plant scheduled a timely replacement, dodging a major breakdown that would have cost them dearly in downtime and repairs. It's a clear example of how AI can save you both time and money.

Example: Optimizing a Wind Turbine Farm’s Maintenance

Wind turbine farms are another great example of AI in action. AI systems keep an eye on turbine performance and wind conditions, scheduling maintenance when the wind is low or during predicted downtime. This smart scheduling minimizes disruptions to energy production and makes the best use of maintenance resources. Plus, it takes into account technician availability and travel costs, ensuring the most efficient team is on the job.

How to Integrate AI into Your Maintenance Scheduling

Building a Strong Data Foundation

To make AI work for you, you need a robust data foundation. That means gathering and organizing data from equipment sensors, maintenance logs, and historical performance records. This data needs to be spot-on, complete, and consistent so your AI can churn out reliable predictions and insights. Investing in your data infrastructure is a must to build a solid AI-powered maintenance system.

Selecting the Right AI Tools and Algorithms

Choosing the right AI tools and algorithms is crucial for getting the results you want. There's a whole world of AI solutions out there, each with its own strengths and weaknesses. You'll need to weigh your options carefully, considering the data you have, the complexity of your maintenance tasks, and how much automation you're aiming for. Tools like robotic process automation (RPA) or generative AI like ChatGPT can kickstart your journey.

Training and Upskilling Your Workforce

Implementing AI isn't just about the technology; it's also about your people. Your team needs to know how to use and interpret AI insights. That means investing in training and upskilling to equip your maintenance staff with the knowledge they need. It's also about fostering a culture that embraces data-driven decision-making, encouraging everyone to use AI to improve their work.

Adopting a Strategic Approach

Getting AI into your maintenance scheduling requires a strategic approach. You need to set clear goals, map out your implementation plan, and manage the change process carefully. Keep an eye on how the AI is performing and be ready to tweak things as needed to make sure it's delivering the results you're after.

The AI Advantage: Weighing the Pros and Cons of AI in Maintenance

Pros

- Boosts efficiency and cuts down on downtime.

- Drives data-driven decisions and optimizes resource use.

- Cuts maintenance costs and extends equipment life.

- Improves safety and compliance.

- Enhances productivity and profitability.

Cons

- Requires upfront investment in AI tools and infrastructure.

- Demands high-quality data and expertise.

- Risks job displacement and may face resistance to change.

- Poses cybersecurity and ethical challenges.

- Risks over-reliance on data and algorithms, leading to a 'black box' effect where decision-making becomes opaque.

FAQ

What types of maintenance can AI optimize?

AI can enhance various maintenance types, including preventative, predictive, and corrective, by analyzing data for better scheduling and resource management.

How does AI handle unexpected events in maintenance scheduling?

AI uses real-time data and dynamic algorithms to adjust maintenance tasks on the fly, ensuring minimal disruption.

What are the cybersecurity implications of using AI for maintenance scheduling?

Protecting sensitive maintenance data from cyber threats requires robust encryption, strict access controls, and continuous monitoring.

Can AI be used to improve maintenance scheduling in remote locations?

Absolutely, AI can optimize resource use and predict equipment failures in remote areas, leveraging cloud and edge computing solutions.

What type of business can benefit from AI maintenance?

From large enterprises to facility management, oil and gas companies, and even municipalities, many businesses can reap the benefits of AI in maintenance scheduling.

Related Questions

What are the potential long-term implications of AI in maintenance scheduling?

Integrating AI into maintenance scheduling heralds a future where predictive, efficient, and optimized operations become the norm. This shift not only cuts downtime and costs but also extends equipment life and fosters data-driven decision-making across industries. As AI evolves, we'll see more autonomous maintenance systems, real-time adaptive scheduling, and advanced predictive analytics, transforming traditional maintenance practices for good.

"Exploring AI Safety & Ethics: Insights from Databricks and ElevenLabs Experts"

As generative AI becomes increasingly affordable and widespread, ethical considerations and security measures have taken center stage. ElevenLabs' AI Safety Lead Artemis Seaford and Databricks co-creator Ion Stoica participated in an insightful dia

"Exploring AI Safety & Ethics: Insights from Databricks and ElevenLabs Experts"

As generative AI becomes increasingly affordable and widespread, ethical considerations and security measures have taken center stage. ElevenLabs' AI Safety Lead Artemis Seaford and Databricks co-creator Ion Stoica participated in an insightful dia

Truth Social’s New AI Search Engine Heavily Favors Fox News in Results

Trump's social media platform introduces an AI-powered search function with apparent conservative media slantExclusive AI Search Feature LaunchesTruth Social, the social media platform founded by Donald Trump, has rolled out its new artificial intell

Truth Social’s New AI Search Engine Heavily Favors Fox News in Results

Trump's social media platform introduces an AI-powered search function with apparent conservative media slantExclusive AI Search Feature LaunchesTruth Social, the social media platform founded by Donald Trump, has rolled out its new artificial intell

Cursor Acquires Koala in Bid to Compete With GitHub Copilot

The startup behind viral AI coding platform Cursor is aggressively recruiting top engineering talent from rival AI firms as it escalates competition with Microsoft's GitHub Copilot. Recent moves include acquiring talent from AI-powered CRM startup Ko

Cursor Acquires Koala in Bid to Compete With GitHub Copilot

The startup behind viral AI coding platform Cursor is aggressively recruiting top engineering talent from rival AI firms as it escalates competition with Microsoft's GitHub Copilot. Recent moves include acquiring talent from AI-powered CRM startup Ko

April 25, 2025 at 12:52:07 PM EDT

April 25, 2025 at 12:52:07 PM EDT

O agendamento de manutenção alimentado por IA realmente transformou a forma como gerenciamos nossas operações. É como ter um assistente inteligente que sabe exatamente quando as coisas precisam ser consertadas. Economiza muito tempo e reduz erros. Só queria que fosse um pouco mais barato! 😅

0

0

April 24, 2025 at 3:14:45 AM EDT

April 24, 2025 at 3:14:45 AM EDT

このAIツールを使ってから、メンテナンスのスケジュールが劇的に改善しました!まるで賢いアシスタントがいるみたい。ただ、最初の設定が少し難しいですね。それでも、使う価値は十分あります!🚀

0

0

April 23, 2025 at 5:04:17 PM EDT

April 23, 2025 at 5:04:17 PM EDT

AI-Powered Maintenance Scheduling has really transformed how we handle our operations. It's like having a smart assistant that knows exactly when things need fixing. Saves us so much time and reduces errors. Only wish it was a bit cheaper! 🤓

0

0

April 22, 2025 at 1:59:25 PM EDT

April 22, 2025 at 1:59:25 PM EDT

이 AI 도구를 사용한 이후로 유지보수 일정이 엄청나게 좋아졌어요! 마치 똑똑한 조수가 있는 것 같아요. 다만, 처음 설정하는 게 좀 어려워요. 그래도 사용할 가치는 충분해요! 🚀

0

0

April 21, 2025 at 11:26:10 PM EDT

April 21, 2025 at 11:26:10 PM EDT

Desde que começamos a usar essa ferramenta de AI, a programação de manutenção melhorou muito! É como ter um assistente superinteligente. A única coisa é que pode ser um pouco complicado configurar no início. Mas vale totalmente a pena! 🚀

0

0

April 21, 2025 at 6:01:52 PM EDT

April 21, 2025 at 6:01:52 PM EDT

This AI tool has seriously upped our game in maintenance scheduling! It's like having a super-smart assistant that keeps everything running smoothly. Only thing is, it can be a bit tricky to set up at first. Definitely worth the effort though! 🚀

0

0